By validating the process, providers may have self esteem in the consistency and dependability in their production methods, resulting in improved products excellent, amplified shopper pleasure, and compliance with regulatory standards.

Ongoing process verification will involve amassing and analyzing info from routine creation runs and making important adjustments to maintain the validated condition of the process.

Furthermore, the process design phase also considers the personnel associated with the process. Appropriate training and qualification with the operators are vital making sure that they have got the mandatory competencies and know-how to carry out their tasks efficiently and regularly.

Furthermore, process design and style includes the choice of suited tools and services which will be Utilized in the output process. Factors which include ability, reliability, and compatibility Along with the process demands are taken into account to ensure smooth and effective operations.

The quantity of detail during the reports really should replicate the relative complexity, business use, and regulatory hazard in the system. The report is commonly structured to reflect the validation approach that initiated the project.

When the process has long been experienced, the 3rd phase concentrates on ongoing checking and analysis of the process effectiveness making sure that it remains on top of things.

Moreover, process validation plays a vital role in guaranteeing check here merchandise basic safety. It can help identify potential challenges and deviations that can compromise the protection of the top products. By addressing these dangers and deviations, corporations can ensure that their products and solutions are Harmless for shoppers to employ.

2. Retrospective Validation: Given that the identify suggests, Here is the sort you execute soon after production. It’s performed if the manufacturing process is full with out going through a documented validation.

twelve.0 Deviations: Any deviation from read more the protocol connected to the production process, Uncooked resources, equipment used, sampling, in-process controls and analytical approaches needs to be authorized and documented inside the batch manufacturing report and also the validation report.

We usually classify process validation based upon the timing of its execution relative on the output plan. As outlined by this description, you will discover four distinctive types of process validation: prospective validation, retrospective validation, concurrent validation, and revalidation.

That is realized by gathering and examining info from several production operates to make certain the process is steady and able to Conference the expected excellent characteristics.

This not simply helps to make sure item high quality and individual protection but will also demonstrates compliance with regulatory requirements.

Jona Tarlengco can be a content writer and researcher for SafetyCulture considering the fact that 2018. She typically writes about basic safety and high-quality topics, contributing to your generation of well-researched posts.

Ongoing process verification entails accumulating and examining info from plan creation operates and generating essential changes to take care of the validated state from the process.

Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Ross Bagley Then & Now!

Ross Bagley Then & Now! Bug Hall Then & Now!

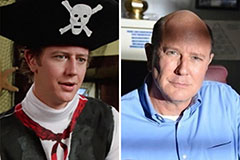

Bug Hall Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now!